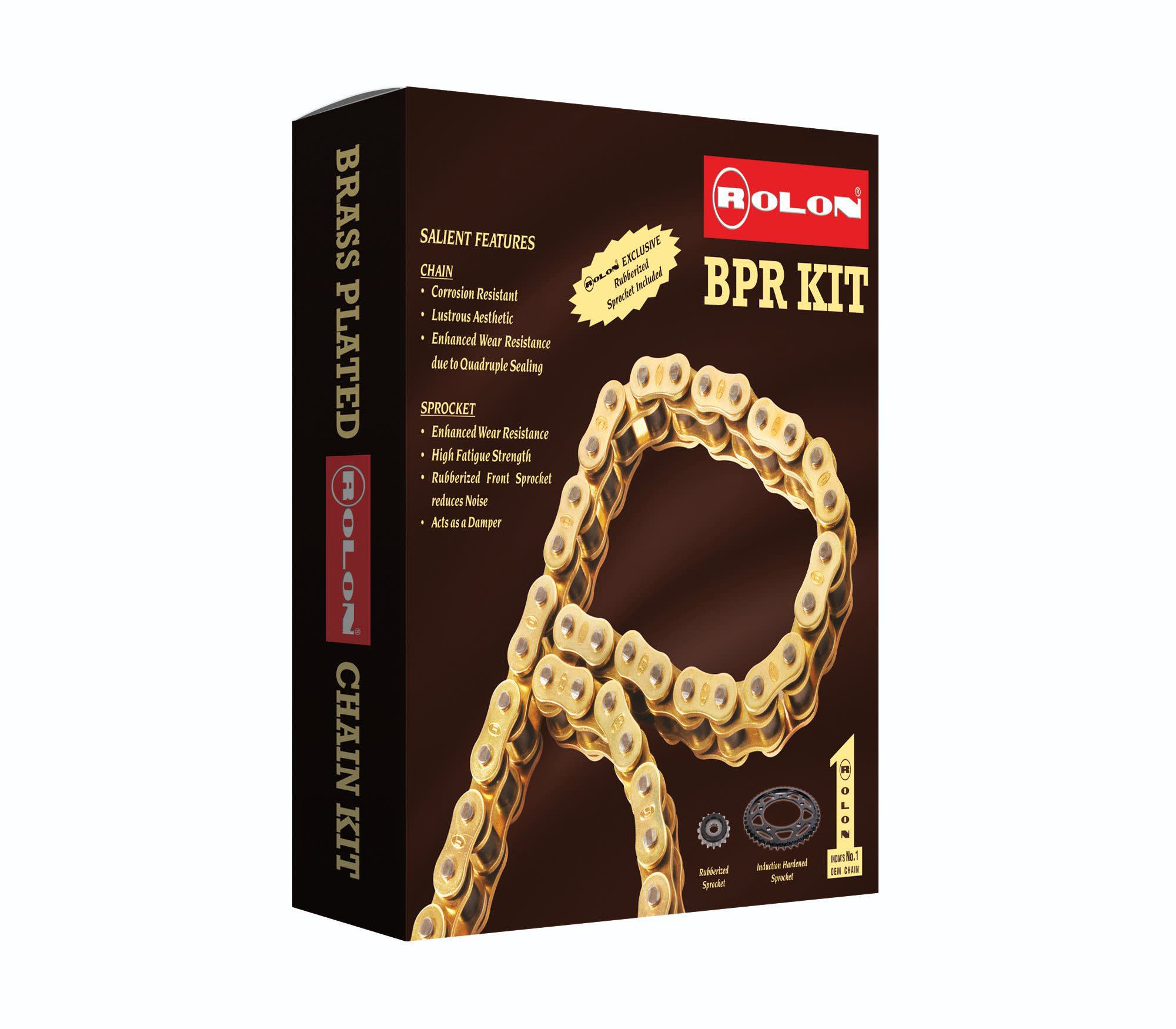

Benelli TNT300/302R Brass X Ring Chain Sprocket By Rolon HAXRC324

₹6,702.00

Or 3 interest free payments of ₹2,234.00 with

Suitable Motorcycle :-Benelli TNT300/302R Brass X Ring Chain Sprocket Kit By Rolon

Upgrade your motorcycle’s drivetrain with the Rolon Genuine Products High-Performance Rolon Chain and Sprocket Kit.

SKU: 324

Categories: Chain & Sprocket, Benelli TNT 300

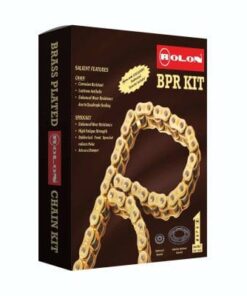

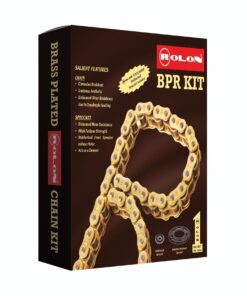

Benelli TNT300/302R Brass X Ring Chain Sprocket Kit By Rolon

- Suitable Motorcycle : TNT 300 / TNT 302R

- Front Sprocket (Z) : 14T

- Rear Sprocket (Z) : 44T

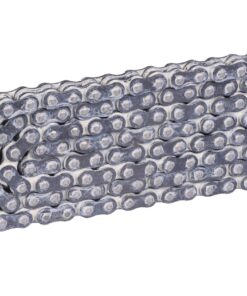

- Number of Chain Links :108

- Both Inner link and Outer link plates are Brass plated

- Brass Plated by Sophisticated Technology

- Enhanced rust protection

- Lustrous aesthetic

- Heavy series/ Solid Bush /’X’ ring chain

- Built rigidly for extreme ride conditions

- Long lasting performance

- Specially designed for Higher strength

- Designed for dignity drive

- Front Sprocket

- Engineered for durability and precision, our front sprockets deliver unmatched performance for motorcycles and bikes.

- Designed with advanced anti-wear technology to ensure maximum power transmission and smoother rides.

- High-quality heat-treated construction for enhanced strength and longevity, perfect for demanding terrains.

- Precision-machined to reduce noise and vibration, offering a quieter and more comfortable riding experience.

- OE-spec fitment guarantees seamless compatibility with your vehicle’s drivetrain system.

- Rigorously tested through 18 production stages and 15 quality checks to ensure top-tier reliability.

- Anti-resistant coating ensures superior protection against corrosion and wear, extending the sprocket’s lifespan.

Rear Sprocket

- Crafted from premium carbon steel, our rear sprockets are built to withstand the toughest riding conditions.

- Induction-hardened teeth for exceptional wear resistance and long-lasting performance.

- Zinc-coated for superior rust prevention, ensuring durability in all weather conditions.

- Shot-blasted finish enhances surface fatigue strength, making it ideal for off-road and muddy adventures.

- Precision-engineered for optimal position accuracy, ensuring perfect fitment and smooth operation.

- Advanced surface protection treatment resists dust, mud, and debris for a hassle-free ride.

- Smooth surface finish reduces friction, providing a quieter and more efficient ride.

| Weight | 2 kg |

|---|

Brand

ROLON

L.G. Balkrishnan & Bros Ltd (LGB) was established way back in 1937. LGB stands proud as the premier manufacturer of automotive chains under the popular brand name 'ROLON'.

The company has 17 chain manufacturing plants, all ISO 9001 certified by Underwriters Laboratories Inc., USA. Three of the manufacturing facilities along with the central functions have been registered to ISO/TS 16949 by UL, USA.

The first chain manufacturer in India to be awarded the ISO 9001 certification. LGB is a recognised Export House - about 10% of LGB's products are being exported to USA, European countries, Australia, New Zealand, South Africa, Japan, Far & Middle East countries.

HSN Code: 87141090

Related products

Chain & Sprocket

₹2,576.00

Sale!

Chain & Sprocket

₹2,708.00

Chain & Sprocket

Rolon Brass Chain Sprocket Kit for BMW G310R/G310GS NXRC 321

₹4,287.00

₹2,561.00

Chain & Sprocket

Pulsar RS 200CC Noise Free Chain Sprocket By Rolon HPOR281NF

₹1,981.00

Chain & Sprocket

₹3,012.00

Chain & Sprocket

₹2,526.00